Copper Bonded / Coated Earthing Electrode ( Solied Rod Type)

Sabo Systems is a leading Copper Bonded Earth Rod Manufacturers. EARTHING ELECTRODE consists of low carbon high tensile steel Rods with molecularly Bonded with 99.9% pure Copper with provision for clamp / Terminal at the top for connecting earthing strip to the Machineries / equipments.

| MODEL NO. | DIA (”) | DIA ( ) |

|---|---|---|

| SCBR 12 XYZ | 1/2 | 12.7 |

| SCBR 12 XYZ | 5/8 | 14.2 |

| SCBR 12 XYZ | 3/4 | 17.2 |

Where

X - Copper bonding thickness (in microns)

Y - Length of rod (in mm)

Z - Threaded / Unthreaded

Good earth rods are commonly made from either copper, stainless steel or copper bonded steel. Copper bonded steel rods are preferred & most popular across the world due to its combination of corrosion resistance, strength, low cost & fairly high conductiveness.

SABO copper bonded steel earth rods are mild steel of very high grade & tensile strength. They can be driven by power hammers to greater depth. Couplers are used to increase the length of copper bonded rods. SABO couplers are made of copper alloy which are corrosion resistance & high strength. These are of two types, compressed type & threaded type.

SABO SCBR are being manufactured in various lengths and dia with plain & threaded ends. Copper coating thickness upto 400 microns are manufactured but recommended to minimum 250 microns.

EARTHING INSTALLATION PROCEDURE:

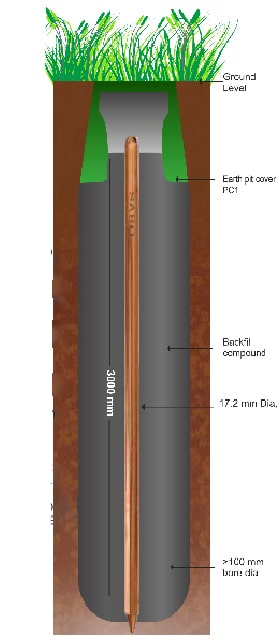

Dig an earth pit of 125 - 150 mm dia of required depth.

Wet the side walls of the earth pit & soil surrounding it & allow water to settle down.

Now make thick paste of SABO back-fill compound by mixing 3kg compound with 2 litres of water.

Pour the paste inside the earth pit and placeearth electrode in the centre of the pit.

Now again make paste of SABO back-fill compound by mixing Skg compound with 5 litres of water and pour inside the pit.

Repeat the process till complete pit gets covered with compound.

Care should be taken while mixing the compound that no debris or plastic or air gap remains in the mixture

Place SABO earth pit cover at the top of the earth pit in such a way that its top level is same as Ground Level.

Measure the earth resistance after couple of days once the compound gets set.

At locations where desired earth resistance is not achieved by single earthpit, then multiple earth pits should be installed at a distance of 3m from each other and connected together by suitable strip.This interconnecting strip should be buried 500 mm below the ground level for interconnection & covered by SABO backfill compound paste.