Chemical Earthing Manufacturers

We at Sabo Systems Pvt. Ltd. are one of the well-established chemical earthing manufacturers. We are known for offering earthing solutions for both industrial as well as residential sector in the form of chemical earthing. Being into this industry for more than two decades, we have become expert in offering chemical earthing solution for lowering soil resistivity to improve electrical safety.

We have experts who are constantly researching on this subject to upgrade the earthing solutions from the traditional earthing systems. At Sabo Systems Pvt. Ltd., we offer enhanced earthing systems considering the safety and demand required by our customers.

Over the past few years, we have observed that chemical earthing is considered safest in comparison to other earthing systems due to a consistent and reliable path offered by them for flowing electrical energy to the earth’s surface. Being one of the reliable chemical earthing manufacturers, we use excellent quality chemical compounds in our electrode that helps in dissipating electrical faults safely. The chemical compounds we utilize in the manufacturing of these electrodes are helpful in lowering the soil resistivity and boost the soil conductivity.

We produce chemical earthing systems using premium grade metal rod along with the best components that makes it durable and long lasting. With our aim to constantly improve these earthing systems, we always test them before the delivery. It helps us ensure that our chemical earthing system is well fabricated and meets all the earthing requirements. At Sabo Systems Pvt. Ltd., we design earthing electrodes that are suitable to use in different environments with ease. We are an ISO approved brand offering chemical earthing systems that come with ISI mark on them. It certifies that all the earthing systems designed and produced by us are reliable and are of optimum quality. We focus on all the industrial and safety standards when it comes to manufacturing chemical earthing electrodes.

Being one of the prominent chemical earthing manufacturers in India, we have set up a benchmark in the industry for producing excellent range of earthing systems for our customers. The flexibility offered by our earthing electrodes make them suitable to use in different types of soil conditions and that is why they are considered one of the versatile chemical earthing systems. These are capable of dissipating electrical energy multiple times and continue to work efficiently for many years. These chemical earthing systems require low maintenance in comparison to traditional earthing system. We at Sabo Systems Pvt. Ltd. are known for supplying chemical earthing system at affordable market rates along with the warranty on each.

Importance of Earthing

Sabo Systems is a leading Chemical Earthing Manufacturers. An effective earthing system is a fundamental requirement of any structure / system for operation and safety reasons. Without earthing, safety of any structure, equipments within it and its occupants are compromised. A well designed earthing system is must for any electrical installation to avoid danger of fault currents as mentioned in various standards as below:

- India: IS 3043:1987 - Code of practice for Earthing.

- Great Britain: BS 7430 - Code of practice for Earthing

- USA: UL 467 — Grounding and Bonding Equipment

- Germany:- DIN VDE 0100 — Earthing arrangements, protective conductors, equipotential bonding conductors

- France: NFC 15-100 — Low voltage electrical installations

The object of an earthing system is to provide as nearly as possible a surface under and around a station which shall be at a uniform potential and as nearly zero or absolute earth potential as possible. The purpose of this is to ensure that all equipments other than live parts shall be at earth potential and also to ensure that operator or attendant or any person shall be at earth potential at all times to avoid shock in case of short circuit or fault current. Hence, low earth resistance is must for obtaining an efficient earthing.

Conductors of suitable section should be used in order to carry expected current. Earthing associated with current carrying conductor is essential for safety of the system and is known as system earthing while earthing associated with non-current carrying conductor or metal is essential for safety of human, animal or property is known as equipment earthing.

Characteristics of good Earthing system :

- Excellent electrical conductivity

- Low resistance and electrical impedance

- Conductors of the sufficient dimensions capable with standing high fault currents with no evidence of the fusing or mechanical deterioration.

- Lower earth resistance ensures that energy is dissipated into the ground in the safest possible manner.

- Lower earth circuit impedance, the more likely that high frequency lightning impulses will flow through the ground electrode path, in preference to any other path.

- High corrosion resistance

- The choice of the material for grounding conductors, electrodes and connections is vital as most of the grounding system will be buried in the earth mass for many years. High hot dipped galvanised electrodes should be used to for this purpose.

- Mechanically robust and reliable.

- Should be maintenance free.

Location for Earth :

- Low lying areas close to the building or equipment are good for locating Earth Electrodes.

- The location can be close to any existing water bodies or water points but not naturally well drained.

- Dry sand, lime stone, granite and any stony ground should be avoided.

- Earthing electrode should not be installed on high bank or made-up soil.

Acceptable Earth Resistance value

The acceptable Earth Resistance at equipment level shall not be more than > 10 Ohm for any electrical installation. However, lesser earth resistance values will more efficiently dissipate the fault currents. Also, there are many equipments specially of communications where low earth resistance values upto <0.5Ohm is required.

Earth Conductor & Earthing Conductor

Most important component of earthing is earth conductor size to be used for earthing. Conductors used are flat type/solid round & stranded cable type. Different countries uses different colour codes, it is preferred GREEN in India.

Copper & steel joints should not be made as it is highly corrosive.

Where copper conductor is joined to Aluminium, the copper should be tinned.

Buried copper conductor should be of minimum 25mL & buried steel conductor of 50rfim. Aluminium conductors are not used for underground connections to earth electrode.

Connections of earthing conductor to earth electrode or other means of earthing should be accessible & joints should be made through non ferrous metal clamps or soldered or exothermic welded.

SABO GI / Copper / Copper bonded Pipe Earth Electrodes

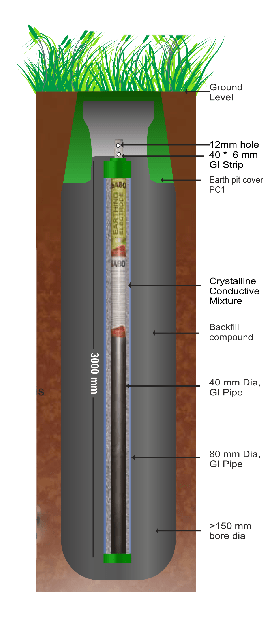

These are made of dual pipe / flat in pipe / single pipe technology. Inner space is filled with highly conductive, corrosion resistant crystalline mixture (CCM) which provides low earth resistance during all seasons.

| MODEL NO. | OUTER PIPE DIA (mm) | INNER PIPE DIA (mm) | INNER FLAT SIZE(mm) | TERMINAL(mm) | TERMINAL sHOLE(Nos’mm) |

|---|---|---|---|---|---|

| SCE 40XYZ | 40 | 19 | 32*6 | 75*32*6 | 2*12 |

| SCE SOXYZ | 50 | 19 | 32*6 | 75*32*6 | 2*12 |

| SCE80XYZ | 80 | 40 | 50*6 | 75*50*6 | 2*12 |

EARTHING ELECTRODE consists of primary G.I.Conductor (outer pipe) and secondary G.I.Conductor (inner - pipe/strip) galvanization is 80 — 100 microns.The secondary Conductoris inserted inside the primary Conductor. The space between the primary and the secondary electrode is duly filled with a highly conductive and non-corrosive compound which safeguards the electrode getting corrode over a long period of time under the soil. All measurments are in MM, PC = Primary Conductor & SC = Secondary Conductor

EARTHING INSTALLATION PROCEDURE:

Dig an earth pit of 125 - 150 mm dia of required depth.

Wet the side walls of the earth pit & soil surrounding it & allow water to settle down.

Now make thick paste of SABO back-fill compound by mixing 3kg compound with 2 litres of water.

Pour the paste inside the earth pit and placeearth electrode in the centre of the pit.

Now again make paste of SABO back-fill compound by mixing Skg compound with 5 litres of water and pour inside the pit.

Repeat the process till complete pit gets covered with compound.

Care should be taken while mixing the compound that no debris or plastic or air gap remains in the mixture

Place SABO earth pit cover at the top of the earth pit in such a way that its top level is same as Ground Level.

Measure the earth resistance after couple of days once the compound gets set.

At locations where desired earth resistance is not achieved by single earthpit, then multiple earth pits should be installed at a distance of 3m from each other and connected together by suitable strip.This interconnecting strip should be buried 500 mm below the ground level for interconnection & covered by SABO backfill compound paste.